Hotel Chocolat Air Conditioning and Air Distribution upgrades

Integrated systems in the production areas ensure constant temperature all year round

The Outcomes:

- Seamless expansion in production process

- All product protected against high ambient temperatures

- Systems filtered to F7 equivalent to meet GMP standards

- Project was delivered on time and budget

The Savings:

- £41K saving in fan power (65% air volume)

- £35K saving in refrigeration power (greater use of free cooling based on higher return air temperature)

- £60K saving in plant costs

- Less than 3 year pay back

*approx. projected savings

The Challenge:

Hotel Chocolat, the luxury chocolate manufacturer, has seen record growth in recent years. Expanded capacity at their Huntingdon production facility was essential. Penmann were commissioned to design and install air conditioning systems to ensure all production areas operated at a constant temperature all year round.

The Solution:

- A detailed survey of the existing process established the heat load so we could accurately design the solution.

- Working with Hotel Chocolat’s Manufacturing Projects Office, we could estimate heat loads for the new areas of the production facility and develop solutions.

- We delivered multiple projects across the various areas with a full turnkey system:

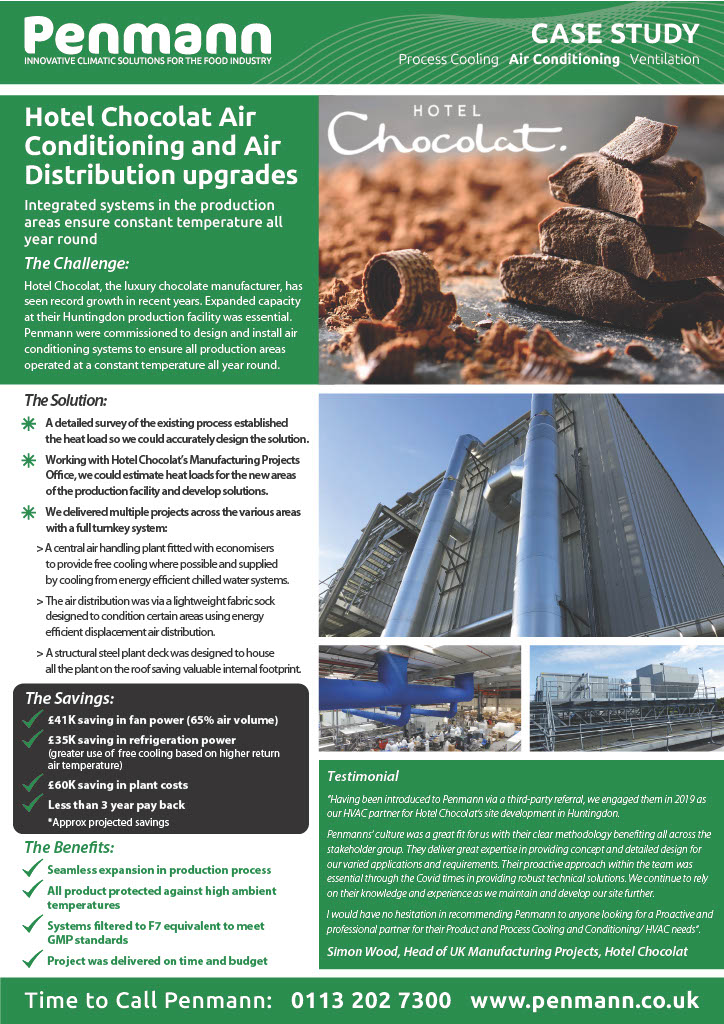

- A central air handling plant fitted with economisers to provide free cooling where possible and supplied by cooling from energy efficient chilled water systems.

- The air distribution was via a lightweight fabric sock designed to condition certain areas using energy efficient displacement air distribution.

- A structural steel plant deck was designed to house all the plant on the roof. Saving valuable internal footprint