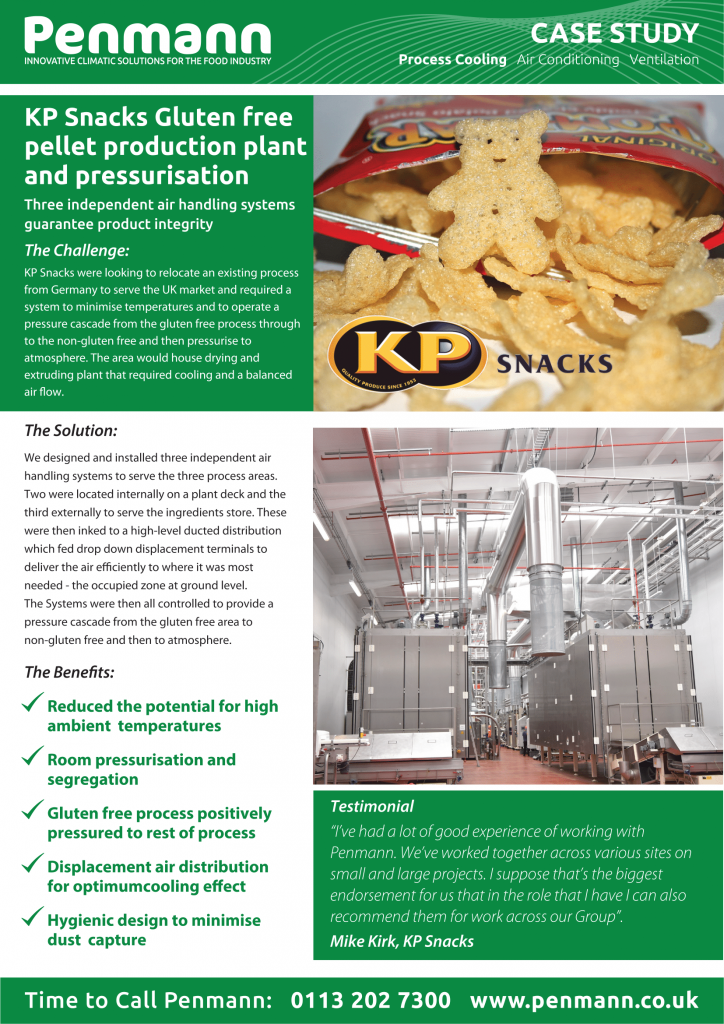

KP Snacks Gluten free pellet production plant and pressurisation

Three independent air handling systems guarantee product integrity

The Outcomes:

- Reduced the potential for high ambient temperatures

- Room pressurisation and segregation

- Gluten free process positively pressured to rest of process

- Displacement air distribution for optimum cooling effect

- Hygienic design to minimise dust capture

The Challenge:

KP Snacks were looking to relocate an existing process from Germany to serve the UK market and required a system to minimise temperatures and to operate a pressure cascade from the gluten free process through to the non-gluten free and then pressurise to atmosphere. The area would house drying and extruding plant that required cooling and a balanced air flow.

The Solution:

We designed and installed three independent air handling systems to serve the three process areas. Two were located internally on a plant deck and the third externally to serve the ingredients store. These were then inked to a high-level ducted distribution which fed drop down displacement terminals to deliver the air efficiently to where it was most needed – the occupied zone at ground level. The Systems were then all controlled to provide a pressure cascade from the gluten free area to non-gluten free and then to atmosphere.

Download the KP Snacks independent air handling systems case study here