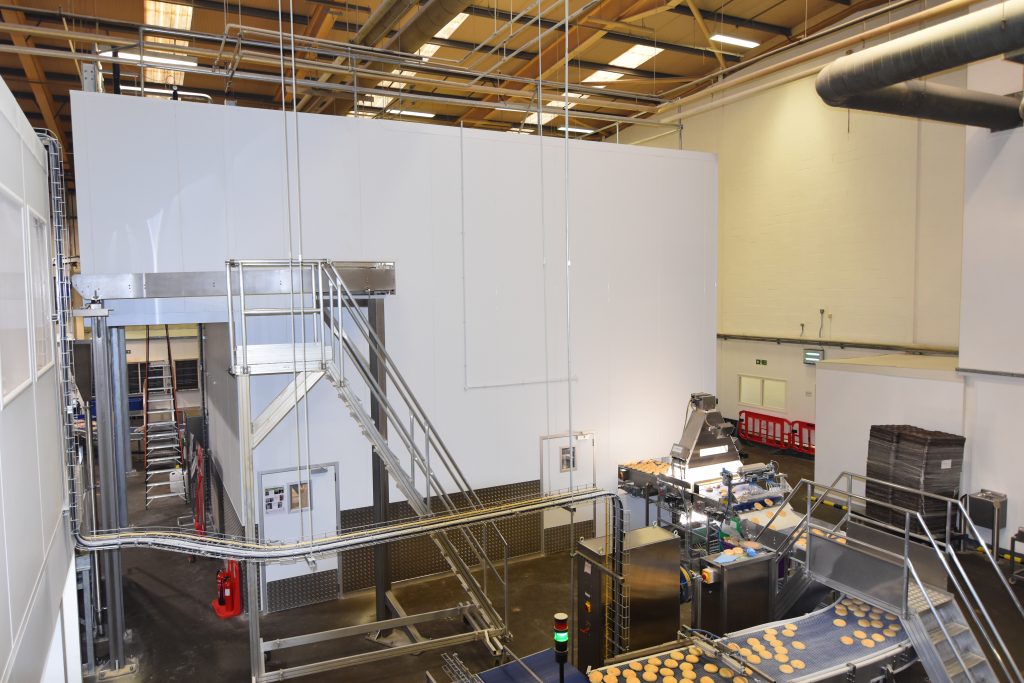

Lantmännen Unibake cooling system

Penmann delivers improved line efficiency with great pay back for Lantmännen Unibake

The Outcomes:

- Improvements in automation

- Increase in throughput on lines

- Potential savings of £90K per annum

- Excellent communication from Penmann throughout commented on and praised by client

The Challenge:

The challenges of these projects included detailed product cooling trials to establish the cooling curve and the complex enclosure of the spiral. Working in a live 24/7 environment is not without difficulty and this was also accomplished through planning and co-operation between the two companies taking into account budgets and timescales that had to be achieved.

The Solution:

Penman completed the work between February and June 2018.

The first project was to ventilate the production area in the client’s highly efficient manufacturing unit in Milton Keynes, to provide personnel cooling but also to remove some product load.

The second project involved the enclosure and cooling of an ambient spiral cooler to enable Lantmännen to increase throughput on their biggest burger bun line by 18%.