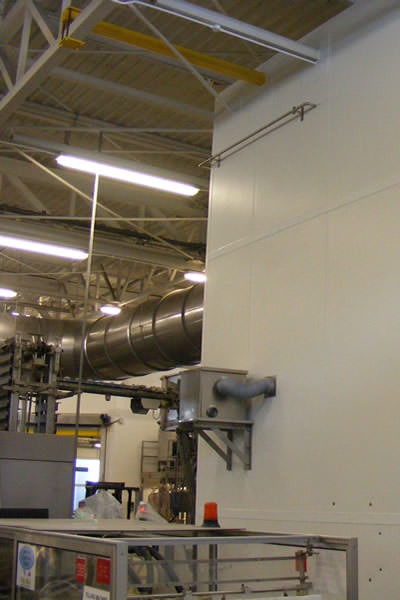

Muller Dairy multihead weigher

Air conditioning and dehumidification solutions to maintain low temperatures and moisture levels

The Outcomes:

- Areas held at design temperature and moisture level 24/7

- Product clumping issues resolved

- Frequency of wash-down reduced

- Line efficiency improved

- Product quality improved

- Complaints reduced

The Challenge:

Food product handling issues were rife for our client. Their sugar-based products in the bulk bag discharge and multi-head weighing room were hygroscopic and kept sticking together, while the conveyor system, which was located on two different floors, also required frequent cleaning.

The Solution:

We enclosed both the areas using a dry wall insulated panel system to speed up the installation and reduce plant downtime.

A full stainless construction was installed around live production in a high hygiene area, which was very congested with existing services. Both areas were individually conditioned to maintain low temperatures and moisture levels, while desiccant dehumidification was employed to achieve a low moisture level.