Temperature humidity and air quality control system for major UK joinery company

Penmann creates a controlled environment for a major new process

The Outcomes:

- Conditioned environment at 26°C

- Absolute moisture levels between 12g/m³ and 5g/m³ all year round

- Area positively pressurised to prevent ingress of contamination

- System filtered to E12 HEPA EN1822 ( 99.5% efficiency )

- System installed to fit round new process

- Project delivered on time and budget

The Challenge:

The brief was to design a system to fit and operate around a new piece of key capital equipment and to understand the restrictions it could place on our design.

We were required to work seamlessly around other trades on a busy installation site.

Throughout the process we were called on to provide flexibility and understanding to adjust the design in real time and cater for changes by our client.

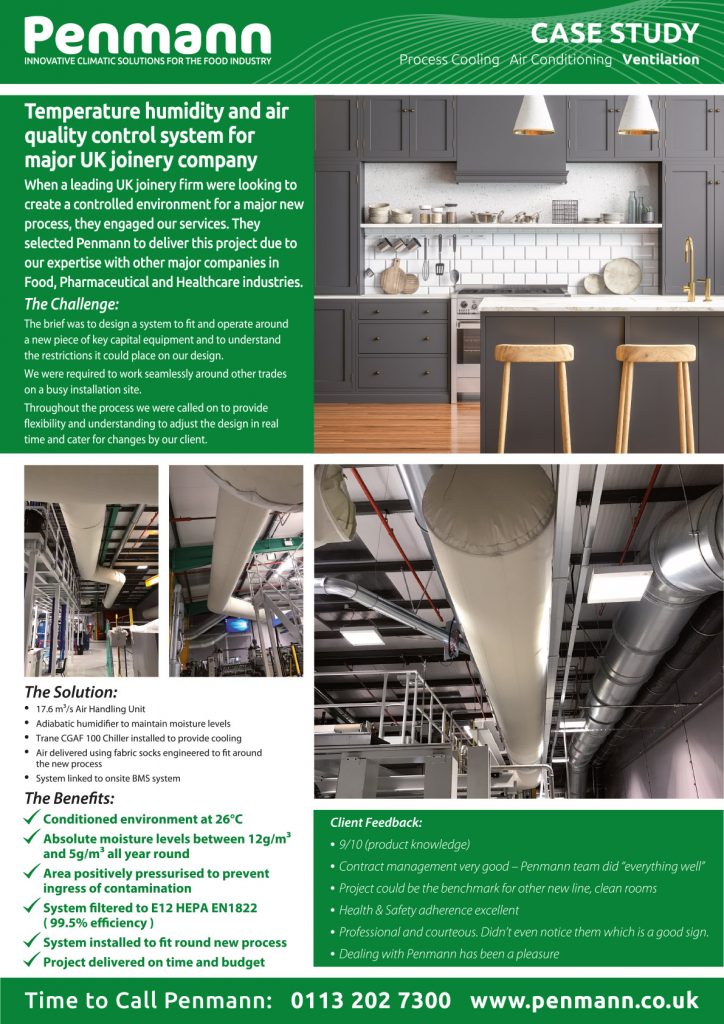

The Solution:

- 17.6 m³/s Air handling unit

- Adiabatic humidifier to maintain moisture levels

- Trane CGAF 100 Chiller installed to provide cooling

- Air delivered using fabric socks engineered to fit around the new process

- System linked to onsite BMS system