A good question. Given Penmann’s experience of implementing this technology for major Food Producers for the last 25 years we are well placed to offer the solution to other industry sectors as a means of safeguarding employees now and into the future.

Teams returning to work

As we now enter the phase of this pandemic where you are formulating plans to get your team back to work, measures must be put in place to maintain social distancing to mitigate against the potential airborne spread of this or other viruses. However, more can be done using tried and tested technology.

Displacement Air Handling – the effective solution

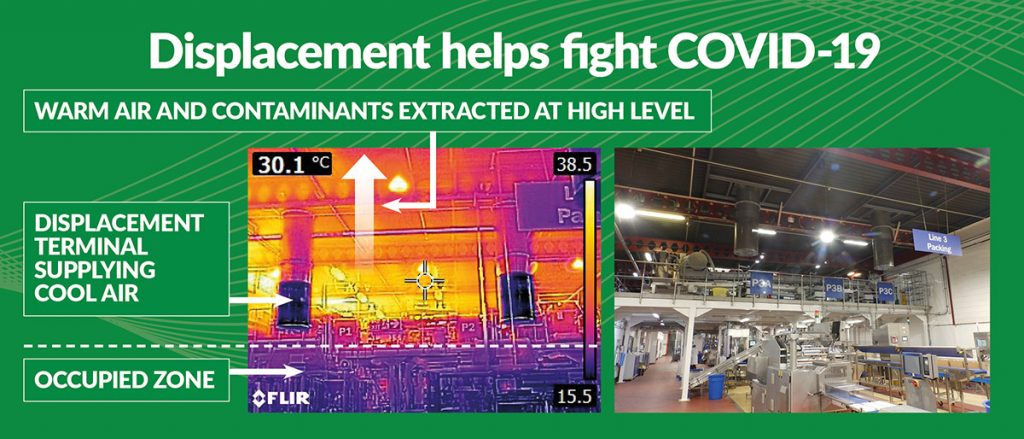

Consider this. Displacement air handling works by introducing air into your occupied working zone at low velocity to reduce entrainment with internal air. Natural buoyance forces ensure that the fresh cool air pools at low level. As this air comes into contact with heat sources – your people and machinery – it forms a thermal plume that takes the warm internal air and many of the airborne contaminants upwards where it can be extracted.

It can be directed either to the outside or in air-conditioned environments, correctly filtered to remove any virus that might be present, before being chilled and reintroduced into the area. This flow of air is often described as a piston effect with cool air pushing warm air upwards away from personnel and is similar to the laminar flow effect used in hospitals and medical environments.

The Benefits

As a result, displacement air solutions provide you with a system which is at least 5 times more effective at removing and diluting potential internal contaminants in your unit Factory or Production area providing enhanced protection for your employees.

The good news is that many existing mixing systems can be relatively easily upgraded and we have over 25 years of delivering such solutions. And the even better news is that displacement will deliver you a raft of additional benefits including energy savings and consequent cost savings.

Don’t just take our word for it

You might want to read how we helped KP Snacks to achieve a range of benefits following an upgrade to a Displacement Air Handling system. Highlights:

- The conversion reduced electricity consumption by £115,000 pa

- Service and maintenance costs significantly reduced

- Filter life extended

- Refrigeration plant only required to operate for 30% of the year

- Improved working environment for team

- Project payback time of just 2.5 years

Read more here about the KP Snacks Case Study

Whatever industry you are in Penmann can provide you with a free of charge assessment of your existing system and outline an upgrade solution.

Don’t delay – Call or Email Penmann today for your free assessment 0113 202 7300 fightcovid19@penmann.co.uk