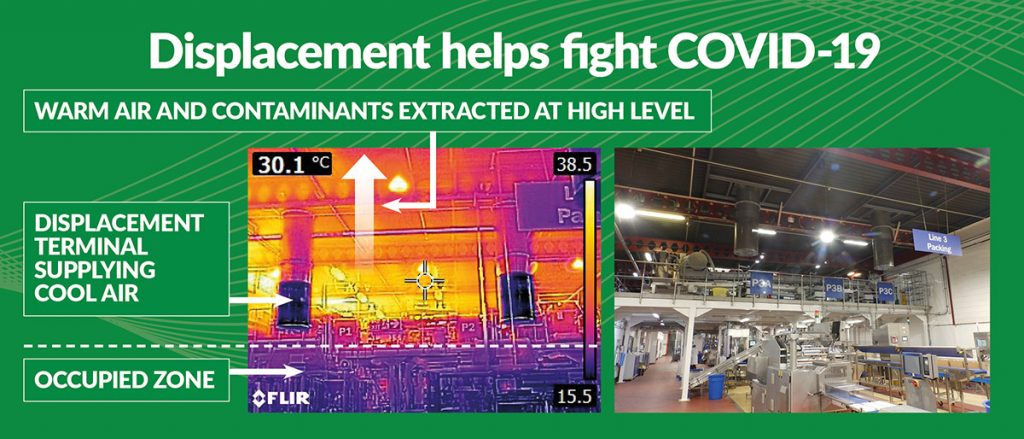

We have spoken about our Displacement Air Handling solutions on a number of previous occasions, but as the country faces new challenges with a dramatic and ongoing rise in COVID cases, we really want to draw your attention once again to our expertise in this technology.

DISPLACEMENT AIR HANDLING IS AT LEAST 5 TIMES MORE EFFECTIVE THAN CONVENTIONAL MIXING SYSTEMS AT REMOVING AND DILUTING POTENTIAL INTERNAL CONTAMINANTS IN A PRODUCTION AREA.

Quite a claim but one we make as we have the experience and measured results from our installations:

- Enhanced protection for employees in a number of settings

- Energy & efficiency savings

- Strong possibility of upgrading existing mixing systems

- Our extensive experience of working in live environments = minimal disruption & downtime

And, additional multiple benefits, too many to list here.

Call us pm 0113 202 7300.

A 2 minute read should convince you to open a dialogue with us:

See our article published in MEM October issue

Read more here on our news feed